Recently I came across an application where multiple motors were failing at a single site. This facility utilized VFDs to control several rooftop AC induction motors. The repeated motor failures raised concerns about the possible causes, prompting a deeper investigation into the relationship between long motor leads, motor failures, and VFDs.

Long Motor Leads + VFD’s

The use of long motor leads can cause issues in VFD-driven motors. Voltage reflections and voltage magnification can occur, leading to voltage spikes that can exceed the motor winding insulation capabilities. These spikes, if left unaddressed, may result in premature motor failure due to insulation degradation.

VFD Strategies for Long Motor Leads

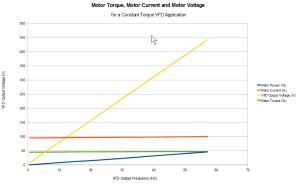

- Adjusting Carrier Frequency: Reducing the carrier frequency of the VFD can help minimize the impact of voltage reflections and the risk of motor failure due to long motor leads. However, this may result in increased audible noise and reduced motor efficiency, so finding an optimal balance is crucial.

- Motor Chokes: Installing motor chokes, also known as output reactors can help mitigate voltage reflection and reduce the risk of insulation breakdown.

- Motor Insulation Ratings: Using motors with higher insulation ratings, such as those designed specifically for use with VFDs, can help protect against voltage spikes and reduce the risk of motor failure.

- Proper Grounding: Ensuring proper grounding practices can help minimize bearing currents and their associated motor failures. While this is not directly related to motor lead length, longer lead lengths can contribute to conditions that cause bearing currents. Some examples of ‘fluting’ and bearing issues here: https://empoweringpumps.com/est-aegis-protect-motors-from-variable-frequency-drive-induced-bearing-damage/

- Cable Shielding: Using shielded motor cables can help reduce electromagnetic interference and protect the motor from high-frequency voltage pulses.

For reference, the formula for the reflection coefficient is below. The greater the mismatch, the greater the voltage amplification factor.

R = (Z_load – Z_source) / (Z_load + Z_source)

where:

R represents the reflection coefficient

Z_load is the impedance of the load (in this case, the motor)

Z_source is the impedance of the source (in this case, the VFD)

The formula for the voltage amplification factor:

V_max = 1 + |R|

where:

V_max represents the maximum voltage on the line

|R| is the absolute value of the reflection coefficient

Another important note is in situations where there are multiple motors driven by a single VFD, the length of cable to each VFD is summed up as the total motor cable length calculation.

Motor Issues Not Caused by the VFD

There are other motor failure scenarios that get misattributed to VFD’s. These may continue occurring even with mitigation techniques above. As such, it’s important to rule these out beforehand. Some common examples:

- Environmental Factors: Exposure to harsh environmental conditions, such as extreme temperatures, humidity, or contaminants, can cause motor failures. These issues may be mistakenly linked to VFDs when they are actually the result of inadequate motor protection or improper maintenance practices.

- Mechanical Failures: Mechanical issues, such as misalignment, imbalance, or excessive vibration, can lead to motor failures. These problems may be incorrectly attributed to VFDs when they are actually caused by issues within the mechanical system, such as worn-out bearings, loose components, or improper installation.

- Overloading: Overloading a motor, either by exceeding its rated capacity or by running it for extended periods at high loads, can result in overheating and failure. This type of failure might be incorrectly attributed to VFDs when it is actually due to improper motor sizing or incorrect application.

- Electrical Issues: Motor failures caused by electrical issues, such as short circuits, phase imbalances, or power quality problems, can also be mistaken for VFD-related failures. These issues may stem from faulty wiring, improper grounding, or voltage fluctuations in the electrical supply.

- Inadequate Lubrication: Insufficient or improper lubrication can lead to bearing wear and premature motor failure. This type of failure may be misattributed to VFD-related bearing currents when it is actually caused by poor maintenance practices or the use of inappropriate lubricants.

- Design or Manufacturing Defects: Motors with inherent design or manufacturing defects may experience premature failure. These failures can be incorrectly linked to VFDs when they are actually the result of flaws in the motor’s construction or assembly.

Conclusion:

While long motor leads can pose challenges for VFD-driven systems, by understanding the risks, adjusting VFD setup and settings, and taking appropriate preventative measures, it is possible to mitigate the risk of motor failures. Additionally, recognizing motor failures that are commonly misattributed to VFDs can help ensure accurate diagnosis and effective solutions. By incorporating proper grounding, choosing the right motor insulation ratings, and utilizing motor chokes and cable shielding, you can enhance the performance of your VFD-controlled moto